General Help

Get information about our website or Droom services

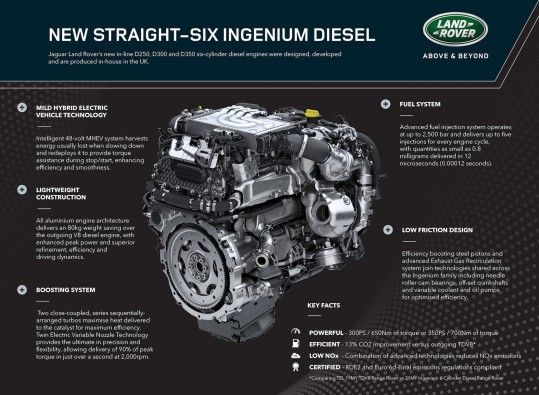

Jaguar Land Rover has rolled out the 15 Lakhth unit of Ingenium engine from its Engine Manufacturing Centre in Wolverhampton, UK. In order to celebrate the milestone, the company has introduced a new powertrain as well in the form of a six-cylinder diesel unit. It will power the new Range Rover and new Range Rover Sport. The advanced in-line Ingenium diesel engine, featuring mild hybrid technology, joins the range of clean and efficient six-cylinder petrol and four-cylinder petrol and diesel engines manufactured at Jaguar Land Rover’s facility in the West Midlands.

Ken Close, Jaguar Land Rover Powertrain Operations Launch Director, said: “We are experiencing unprecedented demand for cleaner-running vehicles, so it’s more important than ever to deliver clean and efficient engines without compromising on the performance or all-terrain capabilities our customers have come to expect. Our Ingenium powertrains offer the very best of both worlds – better fuel efficiency and lower emissions, and even greater torque for a more responsive and engaging drive." Developed and manufactured in-house in the UK, Jaguar and Land Rover’s all-aluminium Ingenium engine designs are modular, flexible and scalable, with common core technologies.

Jaguar Land Rover will continue to develop its Ingenium technology, continue to advance the electrification of its model line-up and establish a concept hydrogen fuel cell powertrain solution. The Engine Manufacturing Centre also houses the assembly of Electric Drive Units (EDUs). The Wolverhampton site is complemented by a growing electrification ecosystem in the Midlands, with the innovative and technologically advanced Battery Assembly Centre at nearby Hams Hall assembling PHEV and BEV batteries. Together, they will power the next generation of Jaguar and Land Rover electrified vehicles. The Engine Manufacturing Centre supplies engines to Jaguar Land Rover’s global vehicle operations, with a large majority of those powertrain units used in UK based facilities including Solihull.

Read Also: